Allanton Shipyard

Eastern’s Allanton Road Shipyard sits on over 300 acres, has an 1,800 linear ft. basin seawall, and has over 6,000 feet of water frontage leading into St. Andrew’s Bay and out to the Gulf of Mexico. A 32,000 square feet (2972.89 sq/m) building houses the steel processing equipment, consisting of a Wheelabrator automated horizontal shot blasting and painting machine for plate and structural members, (3) 10-ton overhead cranes, a Davi MCB130 1-5/8” Plate Roll, a Cincinnati 175-ton Press Brake, a Pacific FK-1250-24 1250-ton Press Brake, a Messer MPC2030 Plasma Precision Cutting Machine, and a Davi MCP 36 Angle Roll. (13) crawler cranes ranging from 175 to 660 ton lifting capacity are used across the facility. The facility also includes an electrical shop, carpenter shop, pipe shop, warehouse, and sandblasting & painting shop, with 46,800 square feet (4,347.86 sq/m) of warehouse space with 4,400 square feet office spaces which staffs our engineering, project management, safety, QA/QC, HR, client offices, and purchasing departments.

The Allanton Road Shipyard has undergone numerous enhancements since the early 1980’s including:

- Multiple in-ground marine railway transfer systems.

- Multiple side launch ways totaling 1,800 linear ft. basin seawall and launch basin expansions with an overall dimension of 760’ (231.65m) in length and 200’ (60.96m) in width.

- Operational in 2016, (1) MG-MESSER, CNC Plasma Arc Burning Machine with (2) x 10’x40′ dry mirror cutting tables, 6″ cutting thickness and 3″ x 45° material beveling.

- Operational in 2010, (1) Ogden Series Arc Welding System, Automated Welding Steel Panel Line.

- Operational in 2018, (1) Davi MCP 36 Angle Roll is a 3 Roll Double Pinch, Digital, Full Hydraulic with “Roll-by-Wire”, and Friction-Free Planetary Guides machine.

- Operational in 2019 (1) Davi MCB130 1-5/8” Plate Roll.

- Steel Processing Building, 400′ (121.92m) long x 80′ (24.38m) width x 25′ (7.62m) height totaling 32,000 square feet (2,972.89 sq/m) containing the Wheelabrator and CNC Plasma Arc Burning Machines.

- Panel Line Building, 560’ (170.68 m) long x 127’ (38.71 m) width x 50’ (15.25 m) height totaling 71,120 square feet (6,607.26 sq/m) building that houses the Ogden Panel Line, the Press Brake and Angle Roller. These (2) large processing buildings are connected allowing for indoor straight-line production.

- (1) 500MT & (2) 250MT self-leveling ship module transporters.

- (15) concrete fabrication platen expansions now totaling 270,460 square feet (25,126.56 sq/m).

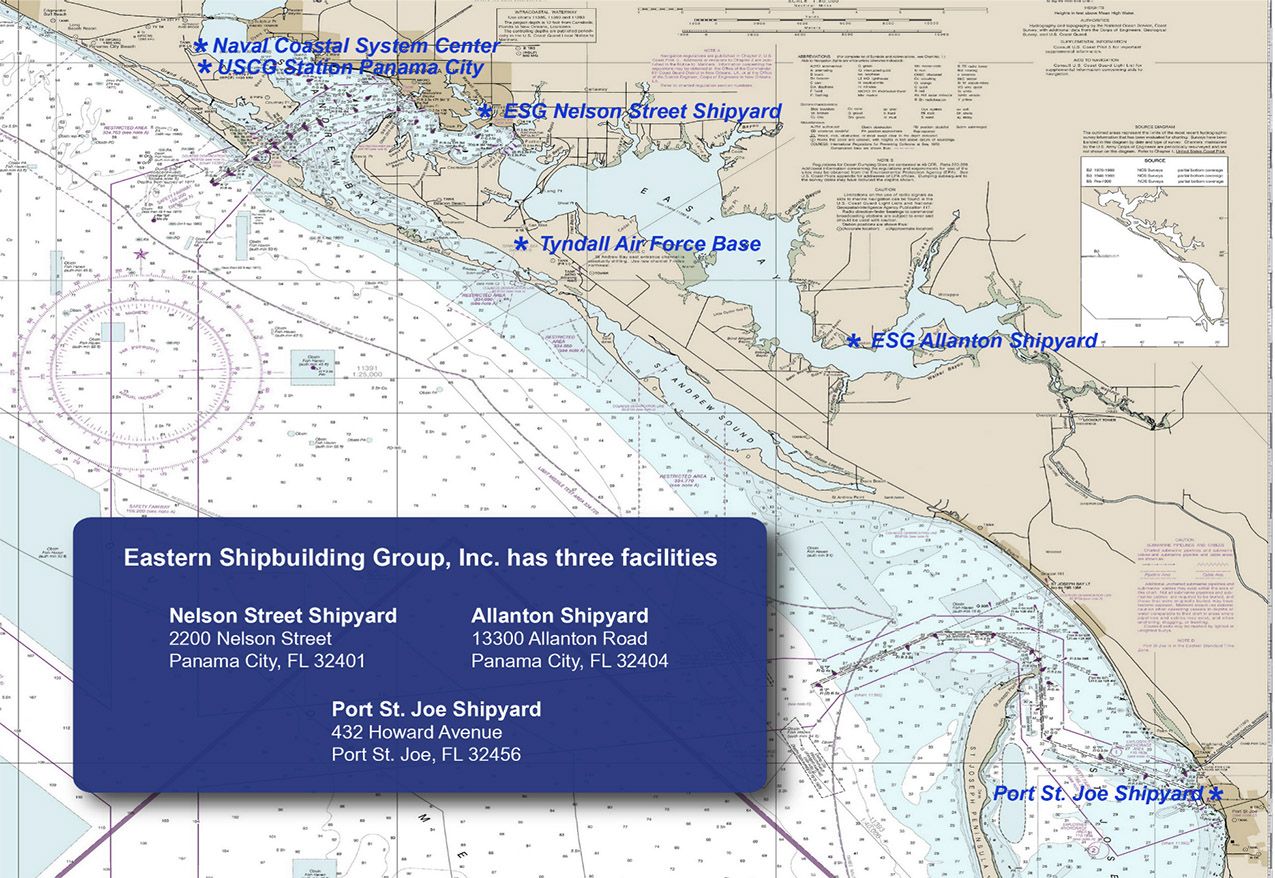

Allanton Shipyard

13300 Allanton Road

Panama City, FL 32404

Phone: (850) 763-1900